Optimising Production with Automated Riveting Machines

In today’s competitive manufacturing environment, industries are constantly striving to improve their production efficiency, precision, and overall cost-effectiveness. One of the most significant advancements in this pursuit is the development of the automated riveting machine. This cutting-edge technology is transforming the way manufacturers apply rivets, allowing for faster production speeds, higher-quality results, and reduced operational costs. Expert Technologies Group is a leader in providing these innovative solutions, helping businesses optimise their manufacturing processes and stay ahead in an ever-evolving market.

What Is an Automated Riveting Machine?

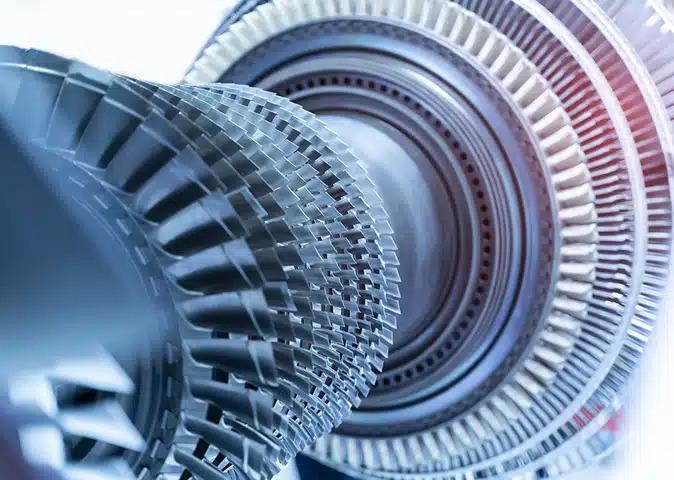

An automated riveting machine is an industrial tool designed to automate the riveting process, which involves joining materials using rivets. Riveting is a method commonly used in industries such as aerospace, automotive, construction, and electronics, where strong, secure joints are essential. Traditionally, riveting has been performed manually, with workers inserting and setting rivets by hand, which can be time-consuming and prone to errors.

Automated riveting machines replace manual labour, automating the entire process and delivering improved precision, speed, and consistency. These machines are equipped with advanced control systems, allowing them to insert rivets quickly and accurately, significantly enhancing production efficiency.

How Automated Riveting Machines Work

The operation of an automated riveting machine involves several key stages, ensuring that rivets are placed accurately and securely:

-

Material Alignment: The materials to be joined are loaded into the machine, where they are automatically aligned for precise riveting. This step is crucial for ensuring that rivets are positioned correctly to form strong, secure joints.

-

Rivet Feeding: The machine uses an automated feeder system to deliver rivets to the correct position. This ensures that each rivet is fed to the right location, reducing the risk of errors.

-

Rivet Insertion and Setting: Once the rivet is in place, the machine applies controlled force to insert and expand the rivet, securing the materials together. The machine adjusts the force based on the material thickness and rivet size to ensure a perfect fit every time.

-

Quality Control: Many automated riveting machines come equipped with sensors or cameras that monitor each step of the process. These quality control systems ensure that each rivet is inserted correctly and meets the required standards, reducing defects and improving overall product quality.

Benefits of Automated Riveting Machines

1. Enhanced Efficiency and Speed

Automated riveting machines can operate at significantly faster speeds than manual methods. These machines can run continuously, increasing production rates without compromising on quality. As a result, manufacturers can meet high-volume production demands and reduce lead times, giving them a competitive edge in the market.

2. Consistent Precision and Quality

Manual riveting is often subject to human error, which can result in inconsistent results and defects. Automated riveting machines eliminate this variability by ensuring that each rivet is inserted with the same level of precision and force. This consistency is essential for industries where joint integrity is crucial, such as aerospace and automotive manufacturing.

3. Cost Savings

While the initial investment in an automated riveting machine may be high, the long-term savings are considerable. These machines reduce the need for manual labour, resulting in lower operational costs. Additionally, by improving production speed and reducing defects, businesses can save money on rework, repairs, and product recalls, ultimately increasing their bottom line.

4. Improved Worker Safety

Riveting can be physically demanding, especially when it involves repetitive motion or significant force. Automated riveting machines take over these tasks, reducing the risk of worker fatigue and injuries. This improves overall workplace safety and ensures that employees can focus on more strategic, high-value tasks.

5. Flexibility for Different Applications

Automated riveting machines are highly versatile and can be configured to handle a variety of materials, rivet sizes, and joint configurations. Whether working with thin sheet metal or thicker, more complex components, these machines can be adapted to meet the specific requirements of each production run. This flexibility makes automated riveting machines ideal for a wide range of industries, including aerospace, automotive, electronics, and construction.

Industries Benefiting from Automated Riveting Machines

Automated riveting machines are used in a variety of industries where precision, speed, and quality are critical. Some of the industries that benefit from this technology include:

1. Aerospace

In aerospace manufacturing, precision is crucial. Automated riveting machines are used to assemble various aircraft components, such as fuselages, wings, and landing gears. These machines ensure that rivets are placed accurately, maintaining the structural integrity and safety of the aircraft. By automating the riveting process, aerospace manufacturers can meet strict safety standards and increase production efficiency.

2. Automotive

The automotive industry uses automated riveting machines to assemble body panels, frames, and other components. These machines help automotive manufacturers increase production rates while maintaining the high-quality standards required for vehicle safety. Automated riveting machines also ensure that each joint is strong and secure, contributing to the overall durability of the vehicle.

3. Electronics

In electronics manufacturing, automated riveting machines are used to assemble enclosures, connectors, and other components. These machines offer the precision required to secure delicate electronic components without damaging them. The speed and accuracy of these machines are particularly beneficial in the fast-paced electronics market, where manufacturers need to meet high demand while maintaining product quality.

4. Construction

Automated riveting machines are used in the construction of large metal structures, such as bridges, buildings, and industrial equipment. These machines speed up the assembly process, ensuring that rivets are installed accurately and securely. This is essential for ensuring the structural integrity and safety of construction projects, especially large-scale infrastructure works.

Why Choose Expert Technologies Group?

Expert Technologies Group is a leading provider of automated riveting solutions, offering state-of-the-art machines that help manufacturers optimise their production processes. Here are some reasons why businesses should partner with Expert Technologies Group:

- Innovative Technology: The company offers the latest in automated riveting technology, ensuring that your production lines are efficient and up to date.

- Customised Solutions: Expert Technologies Group works with clients to develop tailored solutions that meet the specific needs of their manufacturing processes, ensuring the best possible results.

- Comprehensive Support: From machine installation to training and ongoing maintenance, Expert Technologies Group provides full support to ensure your automated riveting machines operate at peak performance.

Conclusion

Automated riveting machines are revolutionising manufacturing by providing faster production speeds, improved precision, and significant cost savings. By automating the riveting process, manufacturers can achieve higher efficiency, better quality control, and reduced operational costs, allowing them to stay competitive in a rapidly evolving market.

Industries such as aerospace, automotive, electronics, and construction are already reaping the benefits of automated riveting machines. With Expert Technologies Group leading the way, businesses can harness the power of automation to optimise their manufacturing processes and continue to meet the demands of today’s high-paced production environments. Investing in automated riveting technology is a step towards enhancing productivity, improving product quality, and ensuring long-term success.

- Business

- Art & Design

- Technology

- Marketing

- Fashion

- Wellness

- News

- Health & Fitness

- Food

- Oyunlar

- Sports

- Film

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- DIY & Crafts

- Theater

- Drinks