Composite Insulation Materials Market Analysis and Forecast (2026–2034)

The Composite Insulation Materials Market, as analyzed by The Insight Partners, is poised for consistent growth during the forecast period of 2026–2034. With the baseline year set at 2025, the market is expected to witness a sustained upward trajectory driven by increasing industrial applications, technological innovation, and global demand for reliable, high-performance insulation solutions.

This comprehensive analysis explores the market’s structure, segmentation, drivers, challenges, and prospects in key sectors such as energy transmission, electrical infrastructure, and advanced manufacturing.

Market Overview and Growth Outlook

According to The Insight Partners, the composite insulation materials market will experience strong, steady growth through 2034, buoyed by expanding applications across electrical, energy, and automotive industries. The report highlights that the market’s value in 2025 serves as the foundation for a progressive expansion outlook, supported by the high-performance nature of composite materials—offering advantages like durability, thermal stability, and lightweight properties.

Composite insulation materials combine two or more substances—such as epoxy resins, glass fibers, and silicone rubber—to deliver enhanced mechanical, thermal, and electrical resistance. This versatility makes them essential in critical installations like cables and transmission lines, switchgears, and busbars, where safety and efficiency are paramount.

Market Segmentation

The market is categorized primarily by type and application:

- By Type:

- Epoxy Resin

- Glass Fiber

- Silicone Rubber

- Stone Wool

Each of these materials caters to specific industrial needs. For example, epoxy resin-based composites are widely used in high-voltage environments due to their superior insulating and structural strength, while glass fiber offers excellent resistance to heat and corrosion.

- By Application:

- Cables and Transmission Lines

- Switchgears

- Busbars

These segments collectively represent the backbone of modern electrical and energy systems. The shift toward advanced grid networks and renewable power integration has heightened the demand for durable insulation solutions capable of withstanding mechanical stress, temperature fluctuations, and environmental degradation.

Market Drivers

1. Rising Demand from Energy and Power Industries

The ongoing development of electricity distribution infrastructure—especially in emerging economies—has significantly boosted the use of composite insulation materials. As nations modernize their power grids and transmission systems, the need for reliable, high-performance insulation increases proportionally.

2. Technological Advancements in Materials Engineering

Continuous innovation in composite manufacturing, including improved fiber-matrix combinations and resin formulations, has amplified performance capabilities. Advanced materials featuring enhanced dielectric strength and temperature endurance are now crucial for next-generation electrical components.

3. Growth in Urbanization and Electrification Projects

Rapid urban expansion and industrialization are driving infrastructure projects that demand efficient electrical insulation solutions. The installation of electric vehicle charging systems and renewable energy grids is further stimulating the need for composite insulators that ensure long service life and safety.

Challenges and Restraints

Despite positive momentum, the market faces challenges such as high production costs and stringent regulatory standards. The sophisticated processes used to fabricate and test composite materials can make them costlier than traditional alternatives like thermoplastics or ceramics. Moreover, manufacturers must comply with international safety and environmental regulations, increasing operational complexity.

Nonetheless, these challenges are expected to diminish over time as economies of scale and ongoing research reduce production expenses and enhance efficiency.

Regional Insights

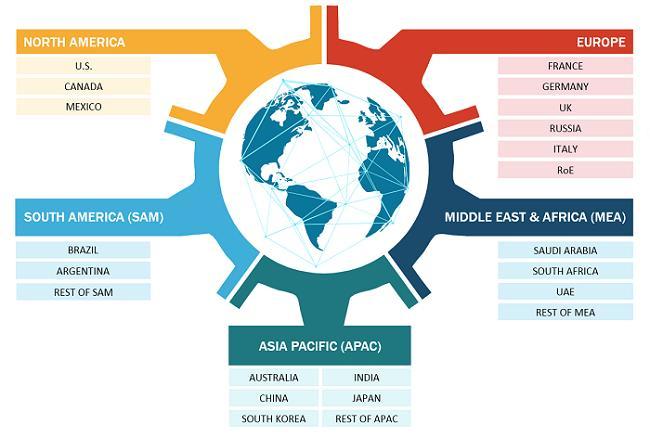

The market outlook varies across regions:

- Asia Pacific is projected to record the fastest growth, fueled by rapid industrialization, infrastructure development, and government-driven energy efficiency initiatives.

- North America and Europe continue to dominate in terms of technological advancements and regulatory compliance, hosting several established composite material manufacturers.

- Middle East & Africa and South America represent emerging markets, showing potential due to growing power transmission and industrial projects.

- Business

- Art & Design

- Technology

- Marketing

- Fashion

- Wellness

- News

- Health & Fitness

- Food

- Spellen

- Sports

- Film

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- DIY & Crafts

- Theater

- Drinks